Grants will give vocational students leg up in working world

When a new training tool can cost $45,000, it makes equipping a vocational school an expensive endeavor. Recently Old Colony Regional Vocational School secured $150,000 in grants, written by Technology Integration Specialist/Data Coordinator Marcia Kessler and Assistant Principal Jackie Machamer that will help students to be job-ready when they graduate.

The school received a $100,000 STEM Equipment and Supplies Grant Program for High Schools grant to improve the advanced manufacturing and metal fabrication department, which is particularly focused on welding.

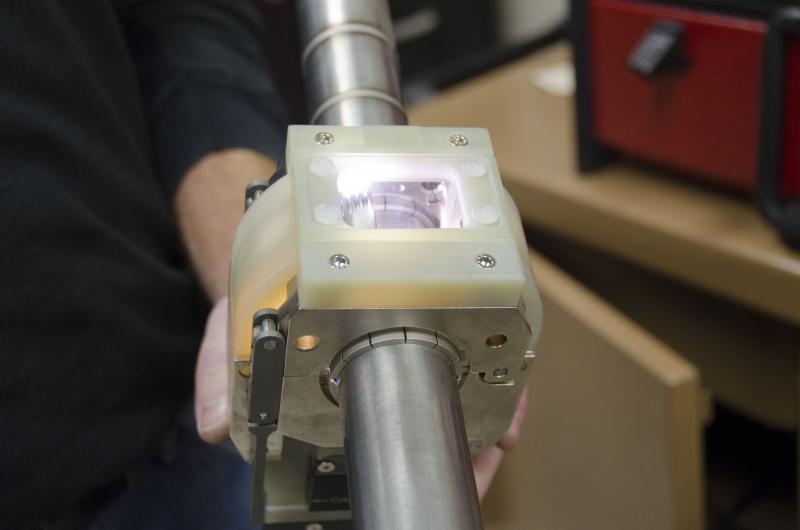

The bulk of that grant, $45,000, went to a new high-purity welding machine – the type of technology used in pharmaceutical factories and other places where cleanliness is a priority.

“A lot of people don’t know that that’s part of this trade,” said metal fabrication instructor Kristoffer Garcia. “Everybody thinks that welding is dirty and nasty.”

An experienced “clean room” welder, Garcia said the demand for more welders in this area is high.

During the summer, “I was working six ten-hour days because they couldn’t find enough guys to do it,” he said.

With the new welding machine, he can teach students a trade that is in demand. Garcia is in talks with a New Hampshire-based welding contractor to get his students certified so they can go straight from graduation to a job.

“If I can get kids here trained ... they can already skip the training process and take the test on the machine and they’d be certified and they could go right to work,” he explained.

The remaining grant money went to more traditional welding machines that update the shop and give students more precise tools to learn welding and metal fabrication.

“It’s a lot better than what they were before,” said Laurinda Gordon, a junior in the welding program.

Garcia agreed.

“They definitely bring us up to date more. The machines are a lot more technical so they see them out in the field and they know what it is,” he said.

That will come in handy as the students often do projects for area townships as well as collaborating with organizations such as Battleship Cove museum in Fall River.

Next door in the machine shop, teachers are pretty pleased with three new lathes they were able to purchase through a $50,000 grant from the state through the Carl D. Perkins Vocational and Technical Act Supplemental Funding.

The old lathes, of which the school still has quite a few, are circa 1975.

“They’re no long used in the industry,” said Michael Ferreira, the first and second year machine tool technology teacher.

The lathes cut through metal to make round objects such as handles and car parts. The belt driven older versions were limited in speed, size and accuracy as opposed to the new gear driven ones, said Ferreira.

“Those blades just couldn’t hit the RPMs that we need today,” said Daniel Ducharme, who teaches the upperclassmen. That lead to a guessing game whenever they were teaching students how to make different projects.

“We’re way behind in the lathes. They couldn’t be retrofitted. The only way to upgrade them is to do what we did,” Ducharme said.

The three new machines are fully computerized with a digital screen and readouts, the only kind of machines found in shops today, according to the instructors.

Without the grant, the school wouldn’t be able to afford such expensive new equipment, as it is not able to incorporate such large purchases into the budget.

And there aren’t really any cheap machines when it comes to these fields.

“You can’t buy a machine for $10,000 that you can actually put in here,” said Ferreira.

Going forward, Kessler and Machamer are looking for any and all grants that can improve the school’s quality of education and student’s employability.

“We wrote [the grants] not just for here, but so when they go out for their co-op experiences or when they go out for employment, they have real experience with the equipment they’re going to find in employment,” said Kessler “That makes a huge difference.”