Old Colony students present prototype to Anchor Insulation

OC Creates, a new program at Old Colony Regional Vocational Technical High School, is aimed at giving students practical experience while also helping small businesses.

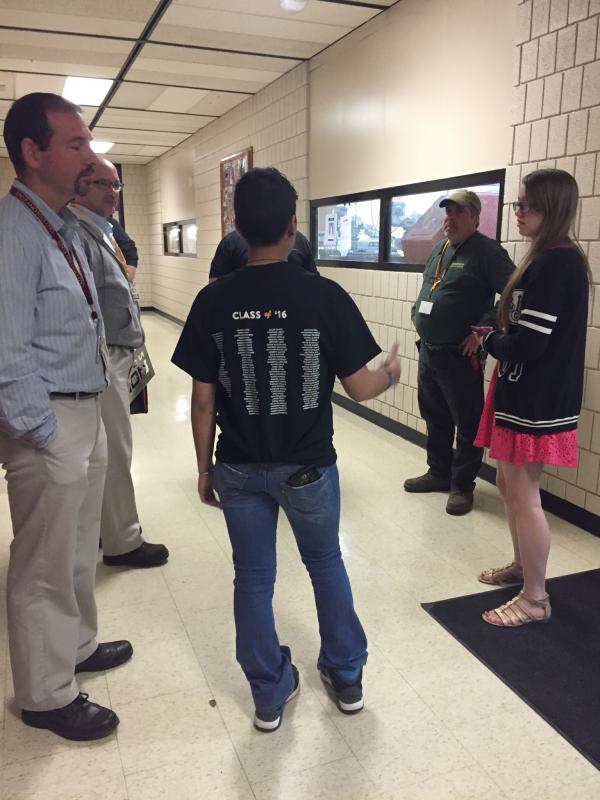

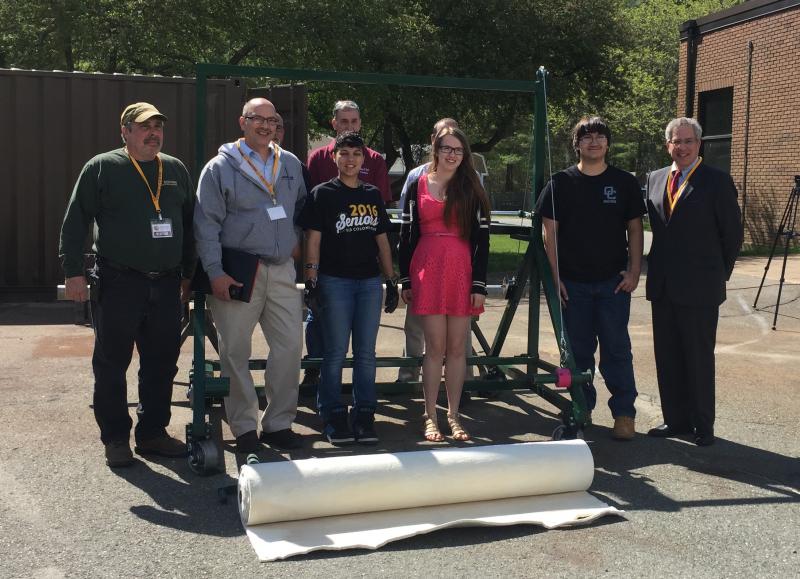

On Wednesday, the school unveiled its first-ever OC Creates prototype, a machine designed for Rhode Island-based Anchor Insulation to reduce the strain of lifting and rolling out heavy rolls of insulation.

The machine was designed and built by three students: Sky Bowker, a junior from Assonet; Felisha Shiner, a senior from Acushnet; and Nate Nicolosi, a junior from Mattapoisett.

OC Creates was an idea born of necessity–the school wanted to improve its program, but needed grant money to do it. In order to get the grant, school officials knew they had to present an innovative request that would support the equipment they requested in the grant.

Essentially, the program would be a way for students at Old Colony to work together to use the skills they are learning in their majors to provide services for small businesses. Namely, they wanted to help spur innovation by reducing the cost of creating prototypes.

The school did not get the grant, but the faculty was committed to the idea. An opportunity came to them when Anchor Insulation emailed the school asking for help.

Teachers Al Amaral from the computer assisted design and drafting program, Michael Ferreira from the machine and tool program and Mike Richard from the welding and metal fabrication program collaborated on the project.

Bowker, a student in the CADD shop, created detailed drawings after speaking with Chris King from Anchor Insulation. However, designing a machine from scratch came with problems.

“I had to completely redesign halfway through the project,” she said.

Shiner, who is a welding and metal fabrication student, was in charge of welding the pieces together to make Bowker’s designs a reality. She experienced problems of her own.

“Building this project seemed pretty cut and dry at first,” she said. “Looking at pictures, I was like OK I got this, then getting into it I was like...OK now what?”

Nicolosi is a machine and tool student, and he created the more specialized parts for the machine, such as the crank.

With the help of their teachers, the students were able to create a successful machine for Anchor Insulation.

“Dealing with these three [students] has been a fun experience,” Anchor Insulation Health and Safety Director Chris King said. “This whole experience has been very impressive.”

Bob Root, a warehouse worker who will directly benefit from the prototype, agreed and is grateful to have a machine that will make his job a little less strenuous.

“This is going to speed up the process a lot and make it a lot easier,” he said.

For Anchor Insulation, this venture was a strictly ergonomic one. For Old Colony, it was a way for students to gain real-world experience and put their skills to the test.

“I learned so many more things than I ever thought I would during this project,” Bowker said. “I learned that your first ideas aren’t always going to be your best ideas...I learned a lot about collaborating. I learned about scheduling.”

And as for Assistant Principal and Vocational Coordination Jackie Machamer, OC Creates has gotten off to the ideal start.

“We’re really pleased and proud of this collaboration,” she said. “It really allows the students to see the interconnected nature of the world of work. I could not be prouder.”